Transforming Bamboo into Boody

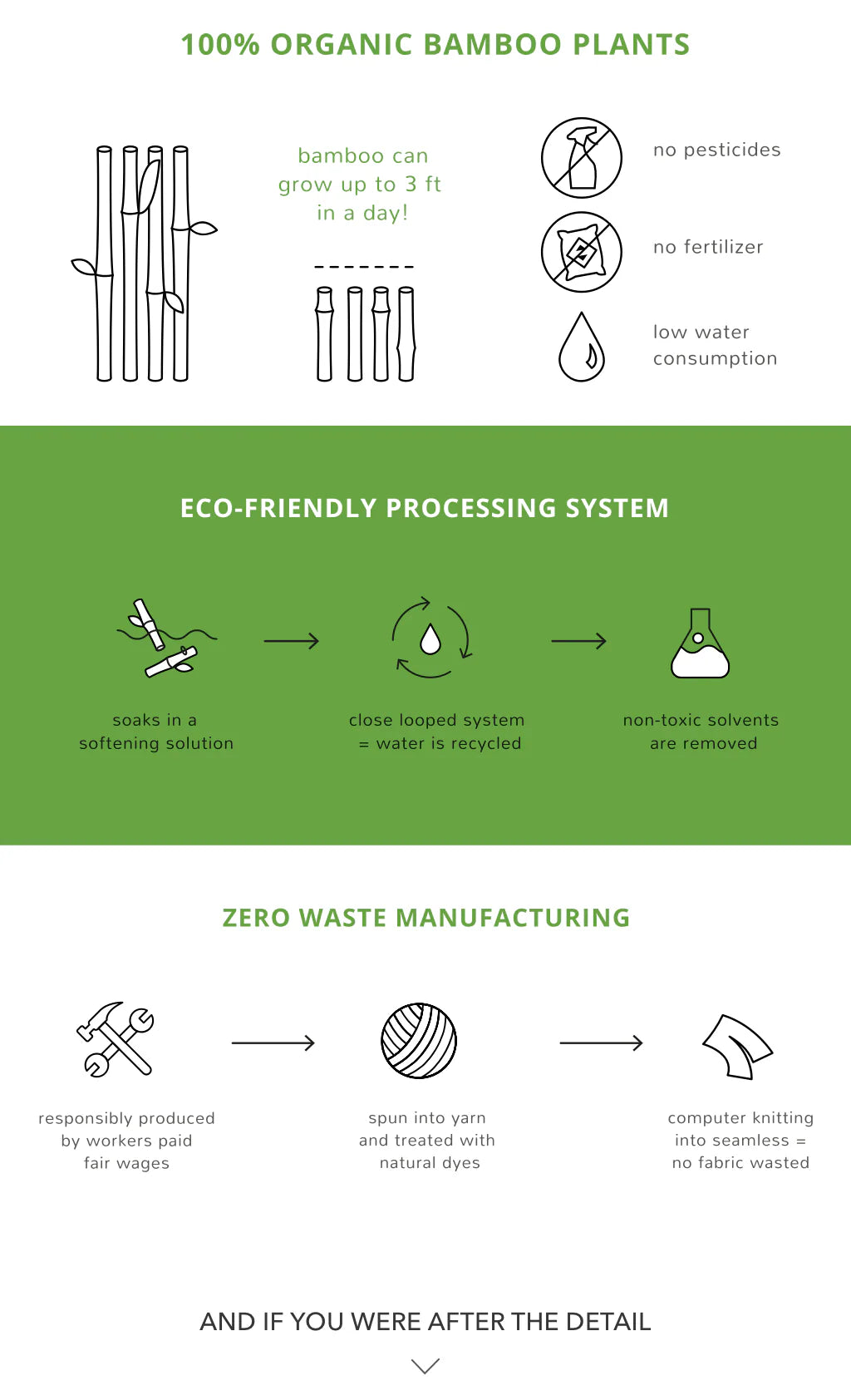

Bamboo has traditionally been used for making huts, baskets, rafts and scaffolding... so how do bamboo shoots become beautifully soft, comfortable Boody garments? Here's the process by which we transform bamboo into Boody Bamboo Eco Wear.

And if you were after more detail, we engaged Green Story to conduct a detailed analysis on the comparative life cycle impact of our products (basically why bamboo is better).

How We Create Boody

1. Grown organic

Our bamboo is grown without fertilizers or pesticides and no irrigation, only rain water.

2. Harvest

First, the green shoots are cut into chunks of raw bamboo.

3. Process

Next, the bamboo is soaked in a solution to soften it. The system is closed loop - all liquid is recycled and all solvents are captured and removed to ensure that the process is as eco-friendly as the bamboo itself.

4. Dehydrate

The dehydration process allows us to extract the bamboo pulp that is then dried into flat sheets.

5. Grind

When the bamboo sheets are completely dry, they are ground into a soft, feathery material.

6. Sew

The soft, feathery material is then extruded and spun into a viscose yarn that we use to knit our garments. The garments are knitted in tubes resulting in very little fabric wastage compared to traditional cut and sew garment manufacturing which wastes up to 20% more fabric (excludes our t-shirts and baby garments which are cut and sew).

7. Your Boody!

The end result is a naturally luxurious fabric that's silky soft and feels fabulous to wear.

A note about our shipping: At Boody, climate change is something that keeps us all up at night. This is why we do everything in our power to lower our carbon footprint, including keeping stages of production together and using mostly sea freight. By undertaking demand-planned shipments, we’re able to control our garment production to minimise any reliance on air freight.

The majority of our deliveries are shipped by boat, reserving air freight for emergency stock and samples, ultimately lowering our carbon footprint. We have plans to measure our carbon footprint more closely and offset any unavoidable emissions.